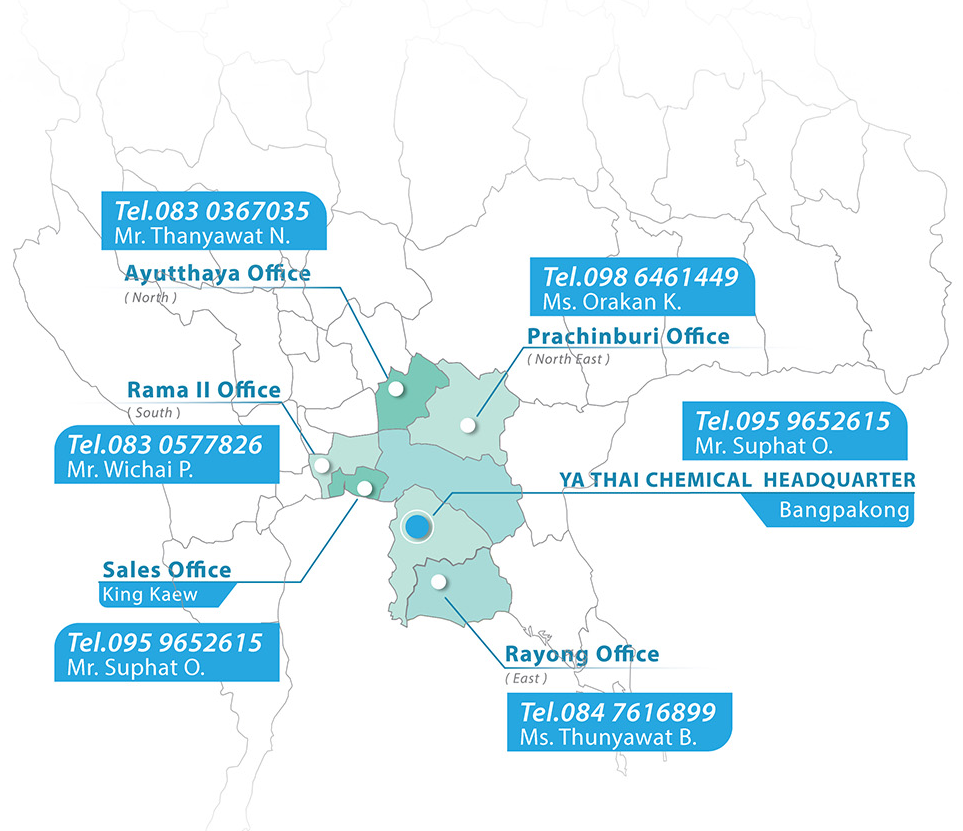

“Located in the Center of Action”

Our factory is located in the Chachoengsao and Chonburi Province. Strategically chosen to be in the center of our 300+ customers in Thailand and close proximity to both the major ports of Thailand.

“Our Service and Swiftness is our Main Strength”

We have a team of close to 30 technical salesperson with three nationalities (Chinese, Japanese, and Thai), distributed in five different regions in close proximity to all the major industrial estates.

If a customer need urgent support, we can be there within the hour.

Our GPS tracked logistics teams is comprised of 6 delivery vehicles, big and small.

Our team is able to make weekly or biweekly deliveries to all the majors industrial zones such as: 304 Industrial park, Amata City Chonburi and Rayong, Nava Nakhon Industrial Zone, Pinthong Industrial Estate, Rojana Industrial Park, Hi-Tech Industrial Park, and TIP industrial Projects.

Due to this arrangement, we are able to offer very flexible delivery terms for our customers.

Our delivery team puts strong emphasis on: Punctuality, Safety, Service, and Cleanliness.

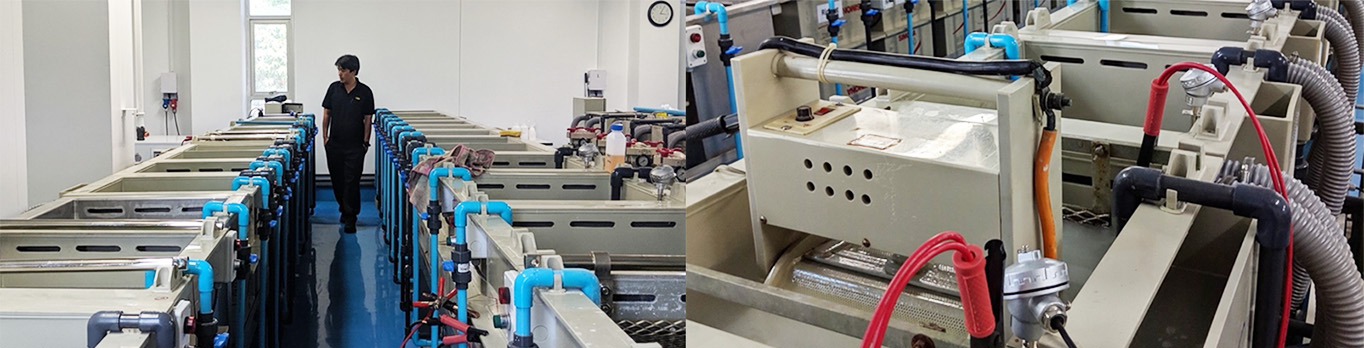

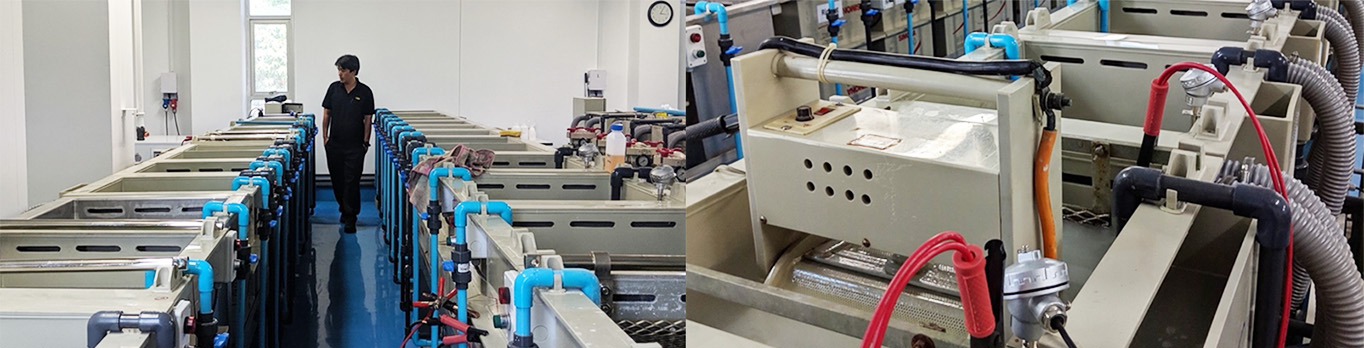

Located in our factory, we have set up a modular pilot plant capable of simulation small scale production of various chemical treatment processes.

Our capability includes: Metal pretreatment, Zinc plating, Zinc Alloy Plating, Copper Nickel Chrome Plating, Electroless Nickel Plating, Various other types of electroplating, Anodising, Passivation, and electropolishing. In addition to immersion processes, we also can simulate spray line processes, such a spray cleaning or spray passivation.

If you require troubleshooting, training, or testing development products, we are able to assist you with our pilot plant.

Our QC and Lab is following the most stringent and puntual standards to make sure our product quality and troubleshooting analysis is the best we can offer.

“Our Factory is why most customers choose to buy from us”

Built in 2005, our factory has been well maintained and developed over the years.

We have two warehouses with a total storage area of 4,000+sqm, and are building more warehouses for the increased demands in speciality and dangerous chemicals.

We take price in the cleanliness of our factory and surrounding facilities. All members of the company must take part in a a monthly big cleaning routine. This teaches all the members of the company the importance of maintaining a clean and tidy working environment.

Starting in 2024, we also installed solar panels to our factory to reduce our environmental impact. We can now claim that our chemicals produced in house is running on green energy.

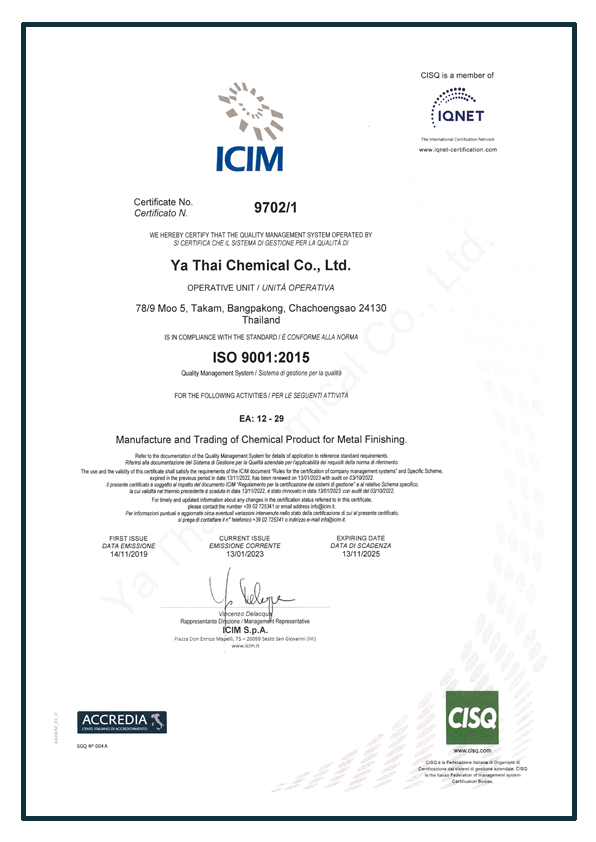

COMPANY’S CERTIFICATE

Our company first obtained ISO certificates in 2004. In 2017 we acquired ISO9001:2015 for

Manufacture and Trading of Chemical Product for Metal Finishing and ISO14001:2015 for

Environmental Management related to Manufacture and Trading of Chemical Product for

Metal Finishing. Now our company obtained Green Industry certificates of Green system level 3.